Precast Concrete Socket Joint Pipes

Design and Specification

- Standard :

- Designed to the MS 881 : Part 1 with Socket Rubber Ring Joint.

- Diameter Range :

- 300 mm - 1800 mm

- Strength Class :

- S, X, Y, Z, Z-Plus (1.5Z, 2Z, ETC)

- L, M, H, H-Plus (1.5H, 2H, ETC)

Crushing Test Loads

| Nominal Size of Pipe(mm) | Class L | Class M | Class H | |||

|---|---|---|---|---|---|---|

| Works Proof Load | Max. Load | Works Proof Load | Max. Load | Works Proof Load | Max. Load | |

| 300 | 20 | 25 | 23 | 29 | 36 | 45 |

| 375 | 20 | 25 | 31 | 39 | 36 | 45 |

| 450 | 20 | 25 | 35 | 44 | 41 | 52 |

| 525 | 20 | 25 | 38 | 48 | 46 | 58 |

| 600 | 20 | 25 | 46 | 58 | 54 | 68 |

| 675 | 20 | 25 | 50 | 63 | 60 | 75 |

| 750 | 38 | 48 | 53 | 67 | 65 | 81 |

| 825 | 41 | 52 | 58 | 72 | 69 | 86 |

| 900 | 46 | 58 | 67 | 84 | 85 | 106 |

| 975 | 48 | 60 | 72 | 90 | 91 | 114 |

| 1050 | 51 | 64 | 76 | 95 | 96 | 120 |

| 1125 | 53 | 67 | 82 | 103 | 106 | 133 |

| 1200 | 58 | 72 | 87 | 109 | 110 | 138 |

| 1350 | 63 | 79 | 96 | 120 | 122 | 153 |

| 1500 | 69 | 87 | 104 | 130 | 132 | 165 |

| 1650 | 75 | 94 | 116 | 145 | 146 | 183 |

| 1800 | 82 | 103 | 124 | 155 | 158 | 198 |

* Due to continuos improvement, the above technical information is subject to change without prior notice.

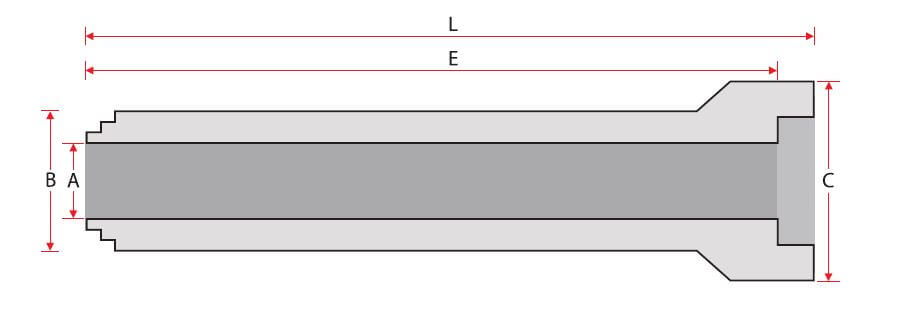

Size

| Nominal Diameter | Effective Length | Overall Length | Barrel Internal Diameter | Barrel External Diameter | Socket External Diameter | Approxim. Weight Per Pipe | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| E | L | A | B | C | S | X/L | Y/M | Z/H | ||

| (mm) | (in) | (mm) | (mm) | (mm) | (mm) | (mm) | Tonne | Tonne | Tonne | Tonne |

| 300 | 12 | 3050 | 3120 | 300 | 370 | 440 | 0.28 | 0.28 | 0.28 | 0.28 |

| 375 | 15 | 3060 | 3138 | 375 | 445 | 535 | 0.38 | 0.38 | 0.38 | 0.38 |

| 450 | 18 | 3060 | 3138 | 450 | 530 | 628 | 0.51 | 0.51 | 0.52 | 0.52 |

| 525 | 21 | 3060 | 3138 | 525 | 615 | 706 | 0.67 | 0.67 | 0.68 | 0.68 |

| 600 | 24 | 3060 | 3155 | 600 | 700 | 805 | 0.86 | 0.86 | 0.87 | 0.87 |

| 675 | 27 | 3065 | 3155 | 675 | 775 | 880 | 0.96 | 0.97 | 0.98 | 0.98 |

| 750 | 30 | 3065 | 3155 | 750 | 860 | 995 | 1.17 | 1.18 | 1.19 | 1.20 |

| 825 | 33 | 3065 | 3168 | 825 | 945 | 1091 | 1.41 | 1.42 | 1.43 | 1.45 |

| 900 | 36 | 3065 | 3190 | 900 | 1030 | 1151 | 1.68 | 1.69 | 1.71 | 1.73 |

| 975 | 39 | 3048 | 3190 | 975 | 1115 | 1254 | 1.96 | 1.98 | 2.00 | 2.02 |

| 1050 | 42 | 3048 | 3180 | 1050 | 1200 | 1342 | 2.27 | 2.28 | 2.31 | 2.33 |

| 1125 | 45 | 3048 | 3180 | 1125 | 1285 | 1444 | 2.59 | 2.62 | 2.64 | 2.67 |

| 1200 | 48 | 3040 | 3180 | 1200 | 1370 | 1501 | 2.95 | 2.98 | 3.00 | 3.03 |

| 1350 | 54 | 3040 | 3180 | 1350 | 1540 | 1694 | 3.71 | 3.74 | 3.78 | 3.81 |

| 1500 | 60 | 3040 | 3180 | 1500 | 1710 | 1854 | 4.65 | 4.67 | 4.70 | 4.74 |

| 1650 | 66 | 3040 | 3180 | 1650 | 1880 | 2060 | 5.64 | 5.66 | 5.69 | 5.75 |

| 1800 | 72 | 3030 | 3180 | 1800 | 2050 | 2260 | 6.70 | 6.73 | 6.79 | 6.85 |

* Due to continuos improvement, the above technical information is subject to change without prior notice.

Overview

TEKUN Produces a comprehensive range of precast reinforced concrete pipes with spigot & socket joint to meet the market demand and requirements. Pipes are manufactured under Malaysian Standard MS 881: Part 1 by spinning process.

Special Pipes

- Special pipes can be designed and manufactured to fulfill the individual project requirement.

- Pipes can be manufactured using Ordinary Portland Cement (OPC), Pulverized Fuel Ash Cement (MASCRETE/EKOCRETE) or Sulphate Resistance Portland Cement (SRPC).

- Pipes Internal Lining can be manufactured using High Alumina Cement (HAC lining), High Density Polyethylene (HDPE lining), Sacrificial Concrete lining, or EPOXY coating.

Application

Used for sewerage, chemical corrosion liquid or storm water conveyance. The joints provide maximum water tightness and protection leaking to the surrounding environment.

Flexible joint pipes also common used in laying high backfill land or underlying ground.

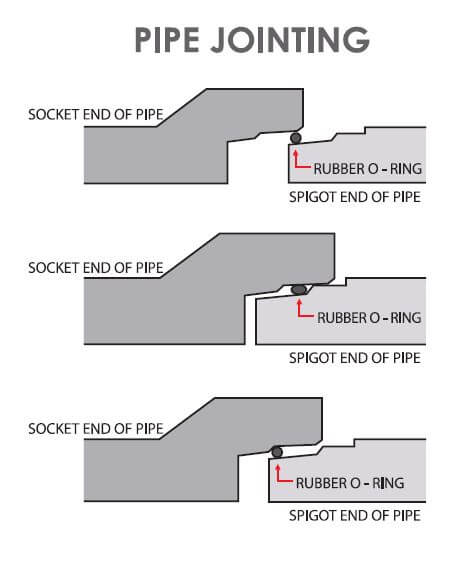

Joint Type

TEKUN Spigot and Socket Joint Pipes come with sliding rubber O-Ring which are designed as flexible joint pipes.